So, I saw something similar to this recently and I thought, "Hey- I have all that 14 and 16 ga wire. This is a good use for it! So I decided to try a pin. I already knew how to make a pin back, since I'm a metalsmith (without an equipment-filled studio at the moment!), and I wanted something that was completely cold-connection because it can be difficult to solder heavy gauge metal with a micro-torch. This is two pieces of 16 ga wire. It's sturdy and it is most definitely a sweater pin. You don't want to put that pin back in a tee shirt or delicate blouse. You'll have a hole that won't go away. But for cardigans, winter scarves, and more loosely or bulky knitted items, this is a fabulous accessory.

I re-learned a few techniques on it, and one of the basic rules of metal working: get your shape the way you want it BEFORE hammering. DUH. Naturally, there will be a few adjustments to make afterwards, but for the most part you want your piece to be in the shape you want it to be before you start hammering it. Hammering, and working the wire in any fashion will work-harden it. This is dead soft wire, stripped from an electrical cable. I have tons of it. Stripping it is difficult because you can't use wire strippers. They mar the metal and create weak points. I strip mine by laying it on a piece of plywood and using an exacto-knife very carefully. Give it a try - this was quick and easy to make and while I'm going to re-make it, since this was a prototype, I'll wear this one this winter.

Remember, when making your pin back, you must twist that wire until it's straight and it provides tension against the clasp or hook. I don't have the hook on this yet, but that pin back won't buckle under pressure. Also, when filing the end to a point, remember that sharp objects can draw blood and tear clothing, so don't make it too sharp. It's for sweaters - it doesn't have to be super sharp.

Search This Blog

Wednesday, May 29, 2013

Hammered Copper Sweater Pin

Labels:

brooch,

copper,

copper wire,

metal work,

pin

Monday, May 27, 2013

Another Viking Weave Bracelet

This is another Viking weave bracelet that I've just finished. I made my own ends by coiling 20 ga dead soft wire around bail making pliers that match the size of the bracelet, and then used the wire tail to create a spiral "cap" to cover the ends of the bracelet. The beads are chrysocola (sp?) and a 4mm sterling bead, and the bracelet is finished with an S hook clasp. I need to re-do the jump ring attachments - was trying for a look that didn't succeed, so those are on the list for a do-over. :)

Sunday, May 26, 2013

Silver Filled Wire vs Sterling Silver or Fine Silver

As a rule, I've always worked in sterling silver or fine silver. With the price as it is right now, it's affordable, but if what I've been reading is any indication, silver is about to skyrocket and by 2014, will be unaffordable for the average artisan. Silver filled wire is an excellent alternative. It wears the same as sterling, it works just as well, as long as you don't use abrasives to polish or buff it. You have to be careful with that because in polishing and buffing, you will wear away layers of silver and base metal may start to show.

People who say they can only wear gold or silver can also wear silver filled or gold filled jewelry. It lasts very well, is a fraction of the price of the precious metal, and if taken care of, will last just as long. I have gold filled pieces that are more than 100 years old and still have the luster of high karat gold, so don't let your customers think they're getting any less for their money.

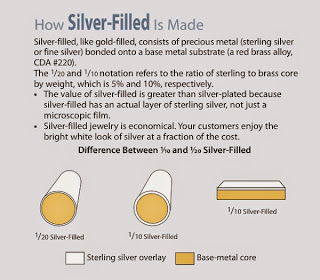

Silver filled metal and wire is made according to the diagram graciously provided by Rio Grande, pictured below:

People who say they can only wear gold or silver can also wear silver filled or gold filled jewelry. It lasts very well, is a fraction of the price of the precious metal, and if taken care of, will last just as long. I have gold filled pieces that are more than 100 years old and still have the luster of high karat gold, so don't let your customers think they're getting any less for their money.

Silver filled metal and wire is made according to the diagram graciously provided by Rio Grande, pictured below:

I intend to start using this for all my head and eye pins and ear wires. I will always have sterling on hand for those customers who absolutely insist on sterling earwires, but if a customer is willing to be educated, they will see that this is a fabulous alternative and it makes the jewelry affordable to them. If silver goes higher than $50 a troy ounce, as it's predicted to go - some say as high as $250 a troy ounce, who will be able to afford to buy it, and/or buy pieces made with it? I don't know about you, but my small sales are the bread and butter of my business. The earrings I currently sell for $20 would wind up being more than $100 a pair and I don't think my customers would buy. They can't afford it.

Give it a try. It works just as well as sterling or fine silver. It solders well (use silver solder) and it patinates just as well as sterling or fine silver.

Labels:

fine silver,

silver,

Silver Filled,

Silver-Filled,

sterling

Saturday, May 25, 2013

Viking Weave In 26 Gauge Sterling Wire

I did this last night - it's my third attempt at this technique and it came out much better than the one in the photo below. Practice makes perfect. I'll turn it into a bracelet, as is.

Labels:

silver,

sterling silver,

Viking weave,

Viking weave bracelet,

woven wire

Viking Weave Bracelet With Freshwater Pearls

Just finished this today. The bracelet is viking weave done with 30 ga dead soft fine silver wire, and the pearls are 3mm freshwater gray pearls wired to the weave. This is my first attempt at viking weave with precious metal - I practiced once on some nasty brass wire, got the hang of it and made this. The chain came out a bit too flexible for my taste, so I decided to wire the clusters of pearls to give it some strength. I used grape leaf motif bead caps to finish the ends, since the pear clusters reminded me of grape clusters. I don't like the black crystals on the ends, so will probably take them off and just use the sterling beads. I think the grape leaf bead ends are a bit heavy for it, both aesthetically and weight-wise, but I didn't have any others in sterling at this point. It's not perfect, but not bad for a second try!

Friday, May 17, 2013

Blue Swarovski Waterfall Earrings

Made these yesterday. Silver plated square wire and graduated sizes and shades of blue and aqua Swarovski crystals.

Labels:

earrings,

handmade jewelry,

silver,

Swarovski Crystal Earrings

Sterling Silver Woven Wire Fish Earrings

These are my latest creation: Sterling frames wrap/woven with 28 ga dead soft fine silver, and Swarovski beads. The earwires are handmade as well. These take about 90 min per earring to make and while easy to make, it can get tricky keeping the weave tight, especially as you get toward the top.

Labels:

beads,

crystal,

earrings,

fine silver,

fish,

handmade jewelry,

sterling silver,

swarovski,

swarovski crystal beads,

wire weaving

Sunday, May 12, 2013

Pricing Hand-made Jewelry Correctly

Ever browsed Etsy or Artfire and seen all those shops with lovely items priced extraordinarily low? And then, when you look at the artisan's sales you find they aren't selling a lot. Here's what I've learned about selling hand-made jewelry online and at craft shows, in case you're interested.

- Profit is not a dirty word. If you are selling something you expect to make a profit, right?

- Hand-made is not synonymous with cheap.

- My time is worth money.

- Buyers can smell a lack of seller confidence. It shows in descriptions, pricing and photography.

- The items I create are worth more than any mass-produced item, since no one else has one like it.

Now, how do you price correctly?

- Know the current market value of your supplies and mark them up at least 100%. Just because you got something on sale doesn't mean you lower your price. You may not find that item one sale again when you run out.

- Think about a labor cost. This is important. If you do not charge for labor you are cheating yourself. Do you think the stores and boutiques where you might shop don't have labor costs built into their prices? Don't sell yourself short.

- If you have to ship an item and decide to offer free shipping, make sure you have calculated the cost of shipping and shipping supplies into the price of your item, otherwise you are losing money.

- If you plan to sell at craft shows, it's wise to assess your market first. Go to local craft shows and watch who is selling and what types of items are selling and for what prices. Know your customer base. If you sign up for a craft show in an area where people are interested only in spending less than $20 for an item, then don't put your best, most expensive items out. They won't sell. Gear your inventory toward the show. Know the demographic that is expected to attend. Plan your inventory accordingly.

At craft shows, always have supplies on hand to custom-make pieces, and always have pieces to work on so customers can see how your lovely items are made - so they can see the work that goes into them. If you're just sitting there with all your pretties laid out, customers will treat it as they would the jewelry rack at a big box store and look for the bargains, and if they don't find any to suit, they will then attempt to haggle with you over price, because to them, it's just another jewelry booth. If they see you working that allows them to come watch and ask questions. You can show them that you are making a pair of earrings or a necklace similar (but not the same) as something you have displayed. They can see that there is labor, time, effort and sometimes back breaking labor, that goes into these creations. Let them see the callouses on your fingers!

If you have done your research and assessed your demographic appropriately, you should have no problem turning a profit at a craft or art show. People want to believe they are getting value for their money, HOWEVER, when they see a pair of earrings that are created from sterling silver and unique bead components and that pair of earrings is priced at $12, they may look at them, but odds are good they won't buy. Why not? You're cheaper than the stores! That's why not. When a pair of sterling silver earrings costs upwards of $50 for something basic and you're selling them for $12 your credibility is called into question. If you don't put a fair market value on your creations, customers won't believe your items are worth purchasing. They will smell your lack of confidence in your own creations and move on.

Is everyone going to buy? No. Some people will be outraged that you'd charge "that much" for something "hand made." So what. Smile and move to the next customer who is actually going to purchase your hand-made item for "that much."

Remember, if you are setting up at a craft show, you only profit once you've covered your supply and labor costs, booth rental, and travel and meal expenses. That means gas and mileage, too...

I'm always open to comments and suggestions, so anyone who has some good input on this subject, please post a comment. I've covered things in brief, and need to head to bed now. It's pumpkin time. :)

Happy creating, everyone!

Subscribe to:

Posts (Atom)